aero

space

Space structures

large and small deployable structures

Space Structures

More than 20 years of experience in development and manufacture of high performance, carbon fiber reinforced plastics, lightweight precision, satellite components for research programs.

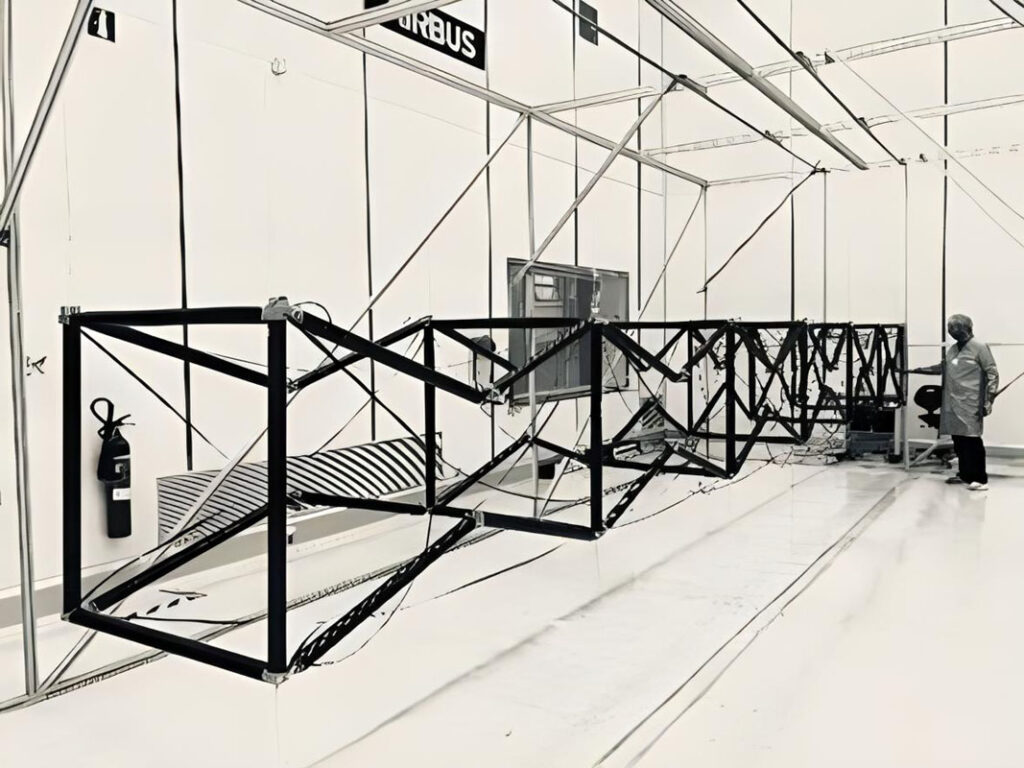

SPACE DEPLOYABLE MASTS

modular construction

We love engineering structures and mechanisms for deployable masts. We have the most priviliged minds that enjoy coming up with engineous solution that combine the latest CFRP materials with cool engineering technology. our motto is make it light, durable and on budget. Just give us a challenge, we are eager to chew on it.

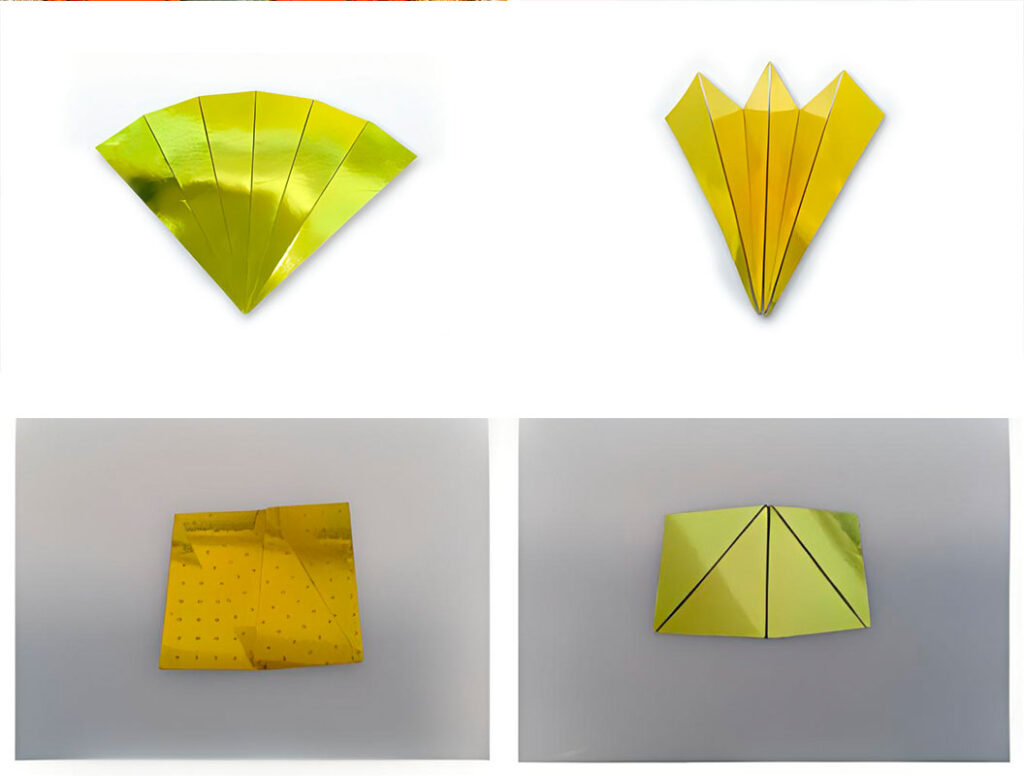

We can design complex shapes that can be constructed, with positive or negative curvature with multiple reversible deployment and folding processes.

The goal is to enhance deployable boom predictability and ground testability, develop designs that are tolerant of manufacturing imperfections, and incorporate simple and reliable deployment systems.

- 1 – 50 meters long

- Ultralight

- Utracompact.

- High stiffness, accuracy and stability.

- Modular, Scalable.

- Passive Deployment mechanism.

- Longest, stifest, lightest, European mast deployed in

0g conditions.

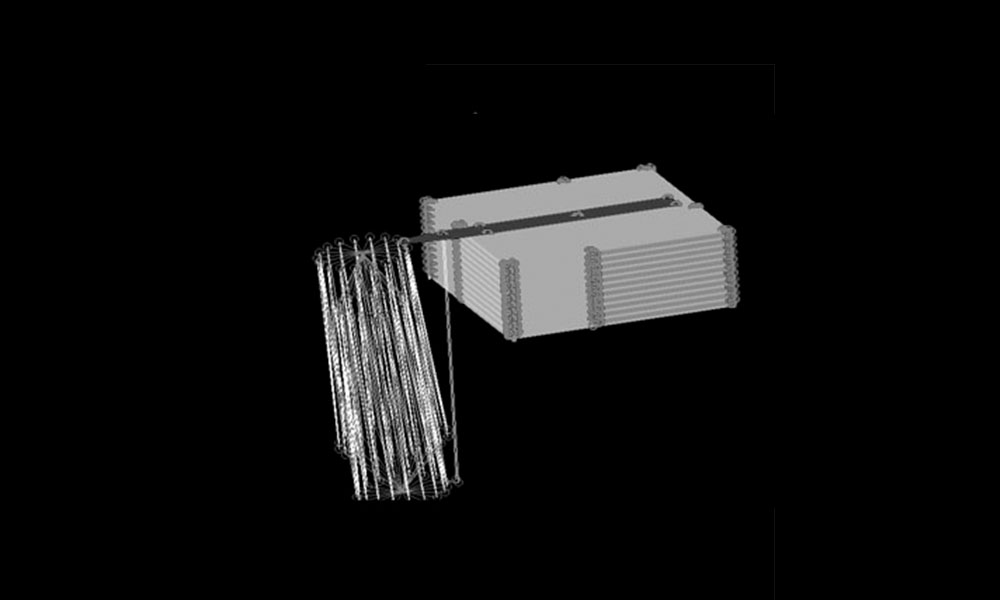

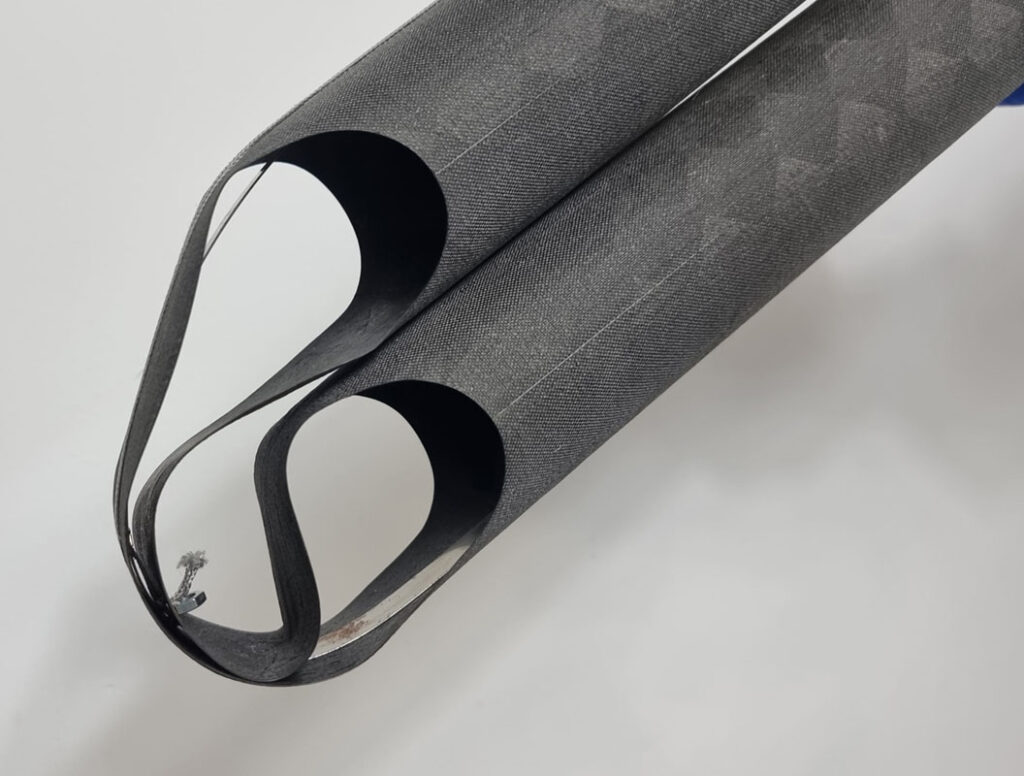

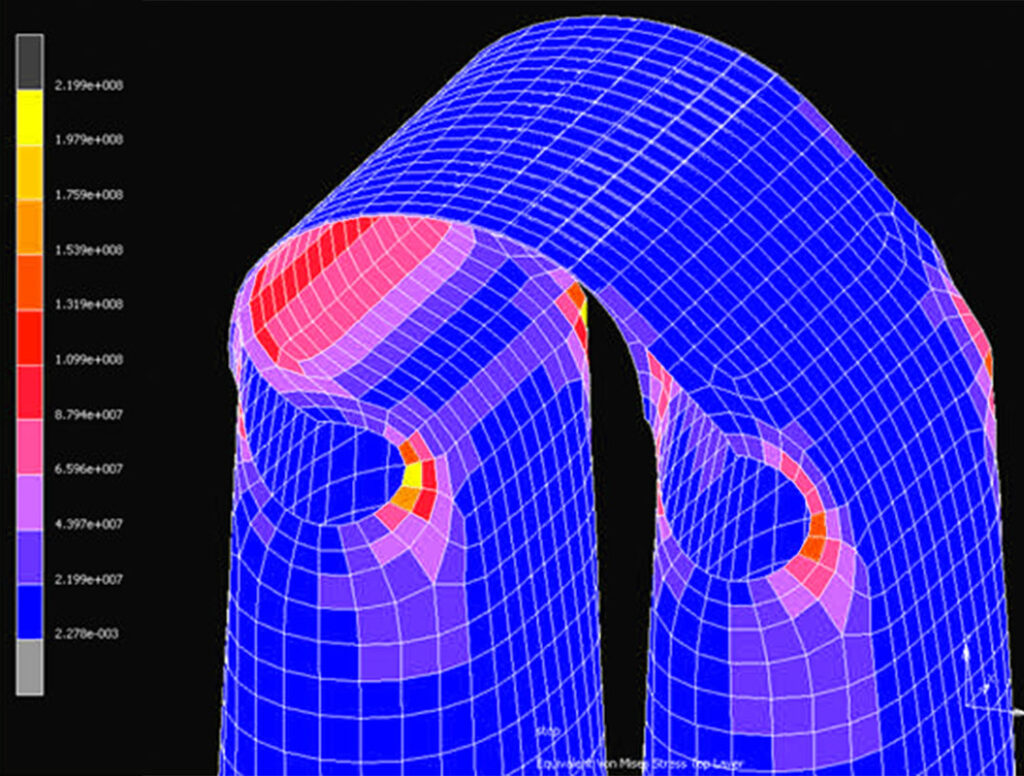

full carbon self deployable booms

The articulated space boom is ultralight, and is made entirely of carbon fiber. This allows you to deploy instruments and systems reliably and accurately. Passive and damped self-deployment, which allows you to minimize the risk of high inertia and shock loads during deployment.

This boom developed by Prosix allows the folding and unfolding multiple times at various velocities and depending on mission requirements reducing structural vibration responses and deployment shocks on elastic hinges.

- Up to 28 m. Full CFRP deployable boom.

- No metallic mechanisms needed.

- Extremely light and accurate

- Carries tip masses such as reflectors or

magnetometers. - Damped deployment

- 100% Carbon Fiber

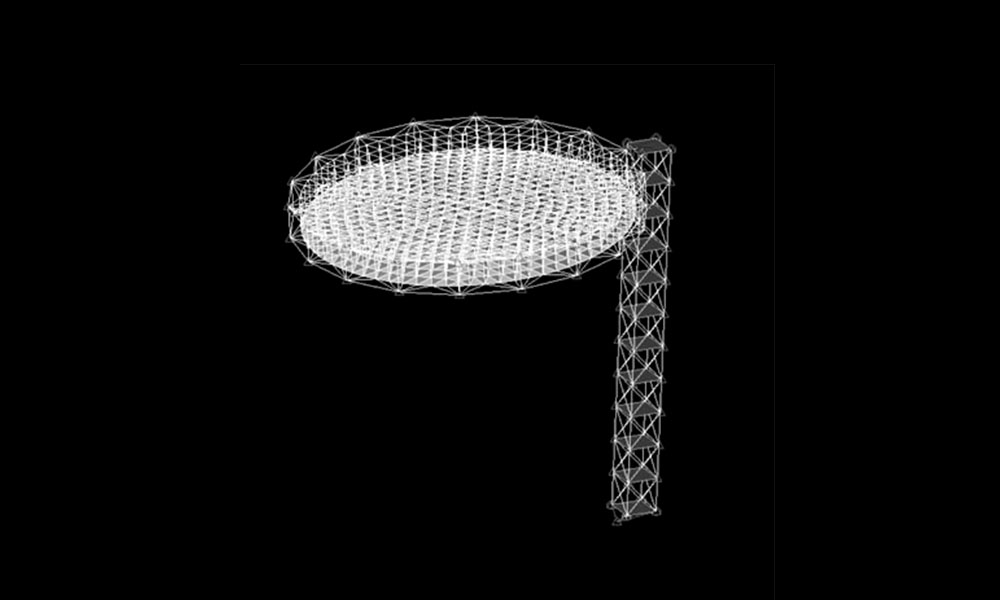

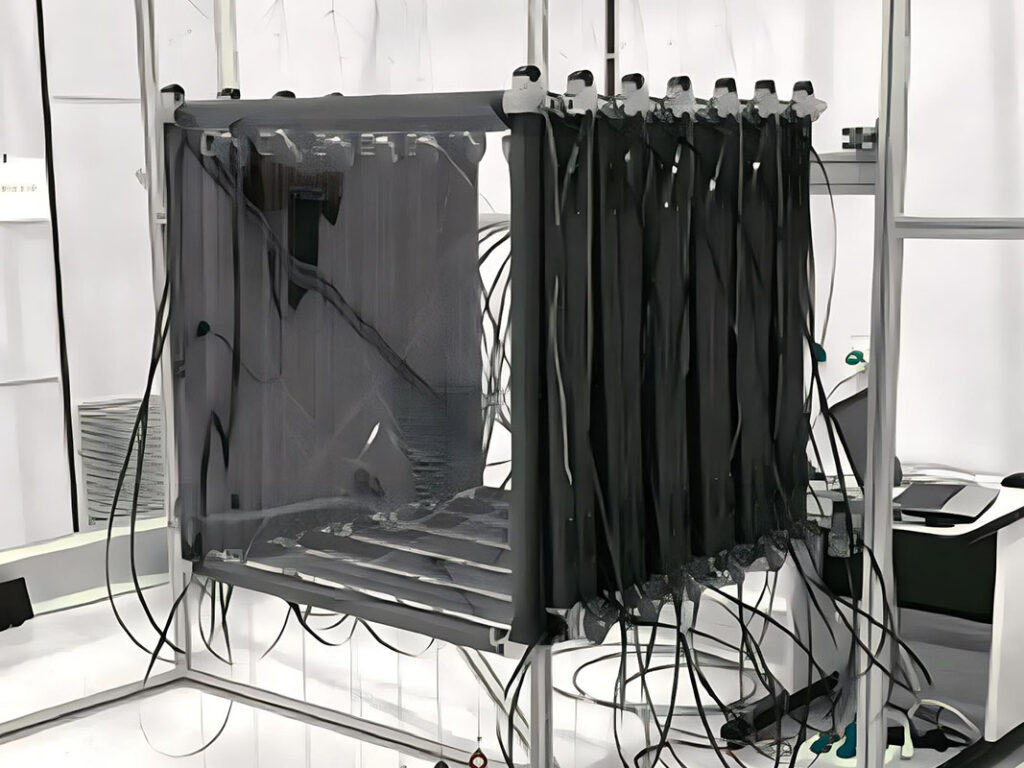

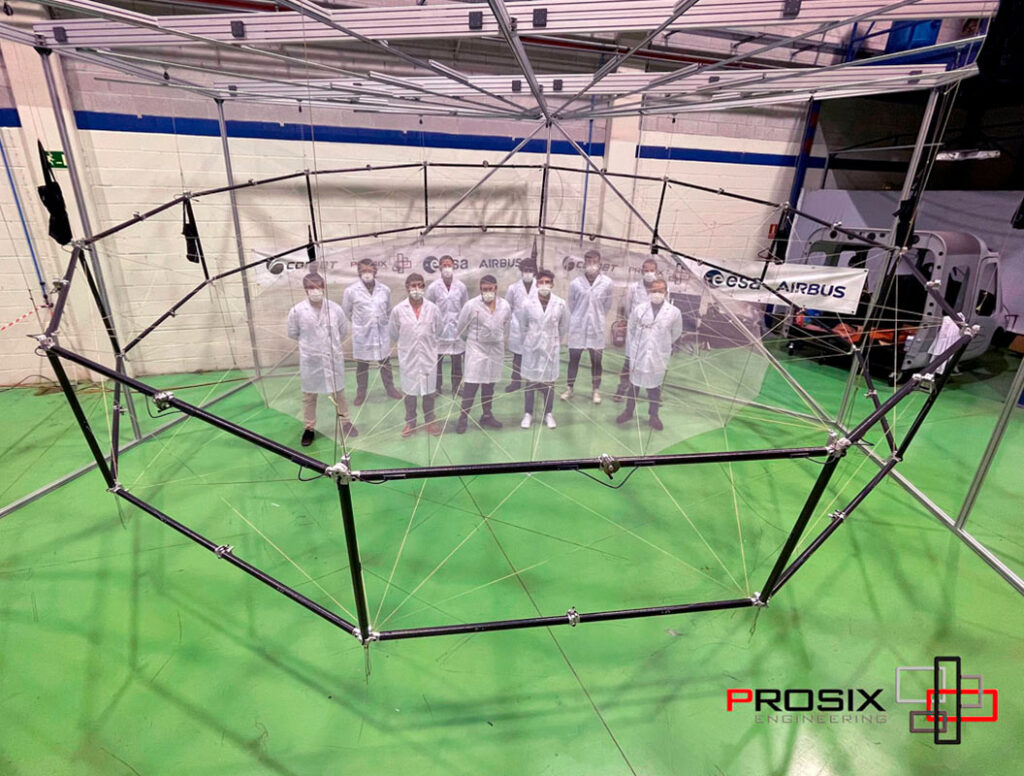

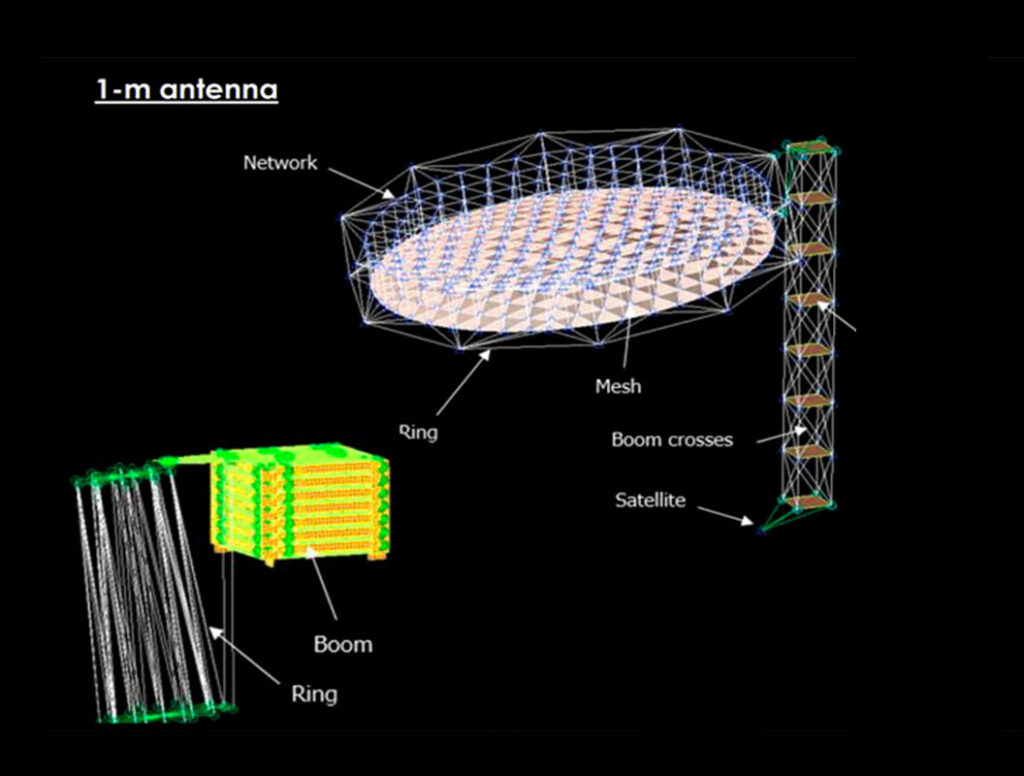

SPACE DEPLOYABLE antenna reflectors

modular construction

We do technology that provides a low weight, compactly deployable support structures suitable for large and small deployable apertures. We have one shot at it, so with our experience, knowledge and brainpower, we build fail safe hybrid composite solutions to ensure the full succes of the deployment.

One of the key challenges for small and large satellites is packaging and reliable deployment of structures and arrays used for communication and scientific instruments.

We can design complex shapes that can be constructed, with positive or negative curvature with multiple reversible deployment and folding processes.

- 0,5 a 16m diameter

- ultracompact

- ultraprecisa

- Repetitive aperture

- Space qualified structures

- Scalability allows to grow in size by employing conventional truss-structure principles.

- Modularity allows further growth, with reduced development costs

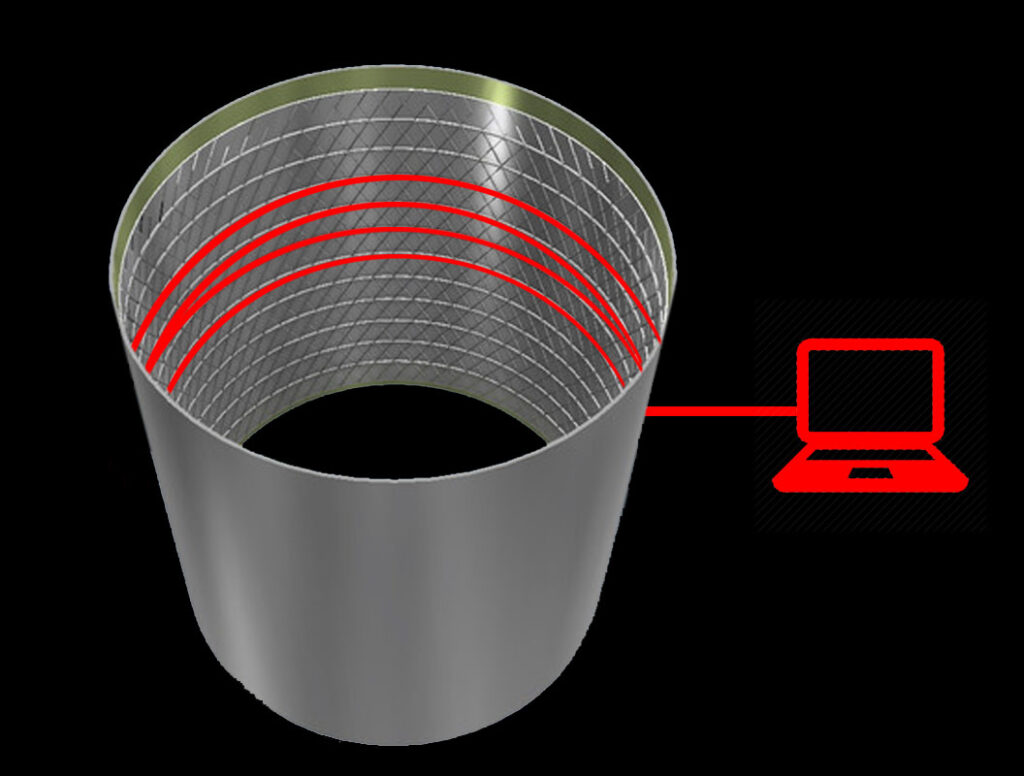

carbon fiber feeds

light wheight space horns

Prosix is bringing disruptive technologies into the space sector by combining the creativity, know-how and experience of academia, the methodology of Space research centres to develop these products.

It is a first in producing the first corrugated horn in 100% CFRP designed specifically for C band frequencies.

In terms of mass density It is 40% lighter than it´s Aluminum predecessor.

Available in a variety of shapes, bands and sizes.

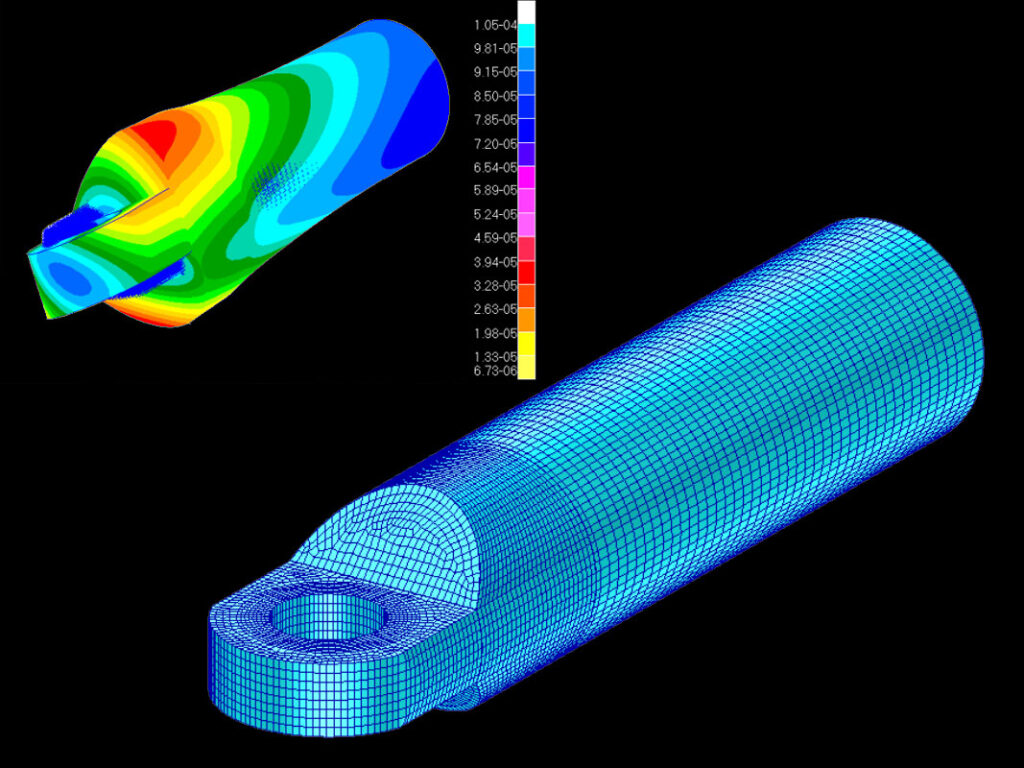

carbon tube struts

INTEGRAL FULL CFRP STRUTS

Prosix’s CFRP struts are a true breakthrough . They are made from integrated pieces of carbon fiber that compose the fittings. which aids versatility and optimilization of production.

Ultra-lightweight to the max. Depending on the length and application, up to 80% of the bulk can be saved.

Thermal expansion of the strut is near zero.

The number of pieces has been reduced. Attachment brackets are integrated into the strut design.

hybrid CFRP STRUTS

Hybrid Struts are made up of composite material tubes integrated with metallic fittings that meet space industry standards.

These struts can be fashioned of a combination of the following options:

- Tubes of composite material (CFRP, GFRP)

- Material selection based on application and desired characteristics.

- Layout to achieve the desired requirements.

- In prepreg cured into autoclave or out of autoclave.

- Variety of metallic fittings (aluminium, titanium, invar, etc.)

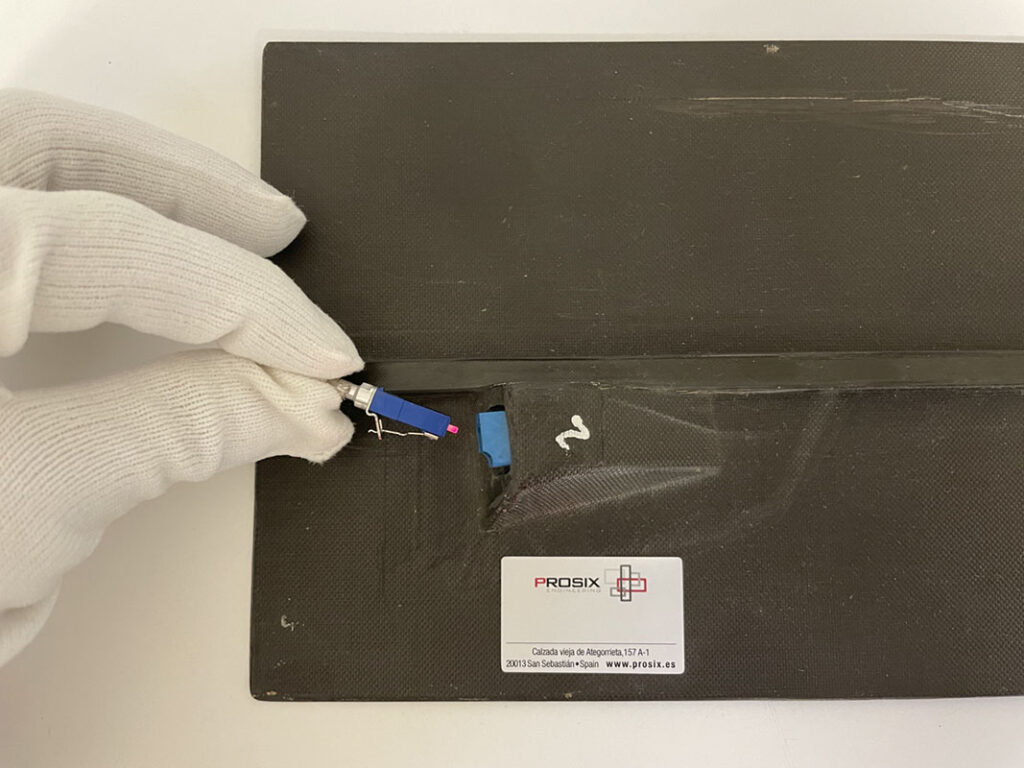

sensoring net bragg in carbon fiber structures

structural health monitoring system

Prosix specializes in Development and production of components with structural health monitoring system inside composites structures for damage detection.

We design components by employing cutting-edge fiber optic systems that enable composite structure monitoring and detection of potential damage that could trigger catastrophic failures, guaranteeing the necessary integrity and reliability of the component.

These components can operate autonomously during the whole operational life of the structure without requiring operator intervention.

We have the capability to develop small simple components, ranging up to large complex space isogrid structures that have this health monitoring capability.